Gas Power Plants: Bridging the gap for a Secure Energy Transition

Renewable energy needs reliable backup during intermittency. Gas power plants (combined cycle and CHP) provide essential grid stability with rapid ramping, lower CO₂ than coal, and hydrogen-blending potential. Explore how they bridge the gap to a clean energy future while preventing blackouts.

The transition to renewable energy is essential for a sustainable future. However, ensuring a stable and reliable power supply remains a significant challenge. Existing renewables, powered by the wind and sun, cannot supply that constant flow on their own. When the wind calms down or darkness falls, generation plunges sharply. This inherent intermittency creates a fundamental challenge for grid stability and energy security during the transition.

This is when energy storage becomes relevant for storing surplus energy during wind stalls and cloudy days. While energy storage offers a promising solution, several challenges remain:

- The Conversion Challenge: Storing electricity directly is challenging, so it must be converted into other forms (batteries, hydrogen, pumped-hydro).

- Over-sizing Requirements: For renewable power generation facilities, which already have a lower capacity factor, to simultaneously power the grid and charge up the storage solutions, we need vastly more wind and solar capacity than peak demand suggests.

- Limited Backup & Durability: Most grid-scale battery solutions offer 4-8 hours of discharge and degrade significantly over the years, thus requiring expensive replacement.

- Weather Vulnerability: Prolonged calm periods, heavy snow, or widespread cloud cover can drain reserves.

The Cost of Perfection

Achieving true 24/7 renewable reliability with current storage tech comes at a steep system-level cost. While the Levelized Cost of Energy (LCOE) for generation is low ($34-$43/MWh for wind/solar), adding sufficient storage dramatically increases it. For example, four-hour battery storage LCOE sits around $104/MWh; roughly 2.4 times the cost of the renewable generation it supports. Scaling this to cover multi-day or seasonal gaps is cost-prohibitive and technically challenging with current technology. Alternatives like pumped hydro are geographically limited, while flow batteries and hydrogen are not high on the technology readiness level, yet.

The Backup Imperative

So, what provides dispatchable power on demand when renewables and energy storage fall short? We need a bridge technology:

- Fossil Fuels (Coal/Oil): Reliable but highly polluting, opposite to our goals.

- Nuclear: Low-carbon and reliable, but complex and slow to deploy as a backup. (More on its potential as a dependable, low-carbon energy source)

- Gas Power Plants: The Flexible Contender. Powered primarily by natural gas (with potential for biogas/hydrogen blends), they offer the unique combination of reliability and lower emissions than coal, acting as a crucial transitional backbone.

Why Gas Plants?

Gas power plants using gas turbines (Brayton Cycle) excel at the rapid response needed to back up renewables, unlike the slow steam plants (Rankine Cycle) of the coal era. Here’s why they fit the backup role:

- Fast Start & Ramp: They can go from cold start to full power in minutes (vs. hours for coal/nuclear), matching sudden drops in renewables or spikes in demand.

- Operational Flexibility: Output can be adjusted quickly to fill the constantly shifting gaps left by variable renewable energy.

- Proven Reliability: A mature technology offering predictable, on-demand power when called upon.

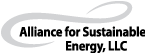

Industrial gas turbines engineered for the long haul are built robustly with heavy-duty materials and components, designed for decades of near-continuous operation. These are optimised to sync to the frequency of the grid. One of their key features is fuel flexibility: they can efficiently burn anything from conventional natural gas and liquid distillates to cleaner bio-gas and even hydrogen blends (paving the way for a lower-carbon future). This rugged design translates to remarkable reliability, often performing for years between major maintenance stops.

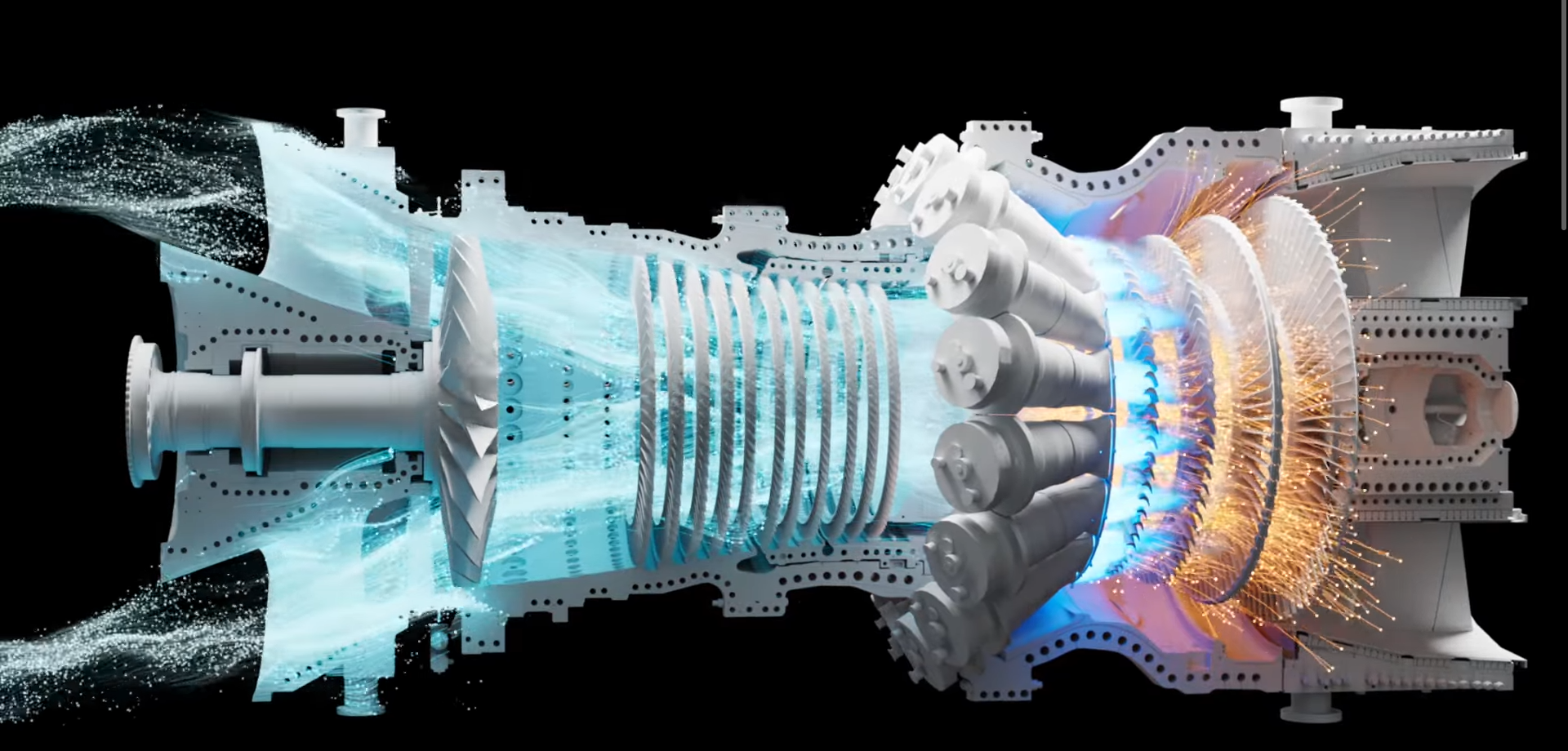

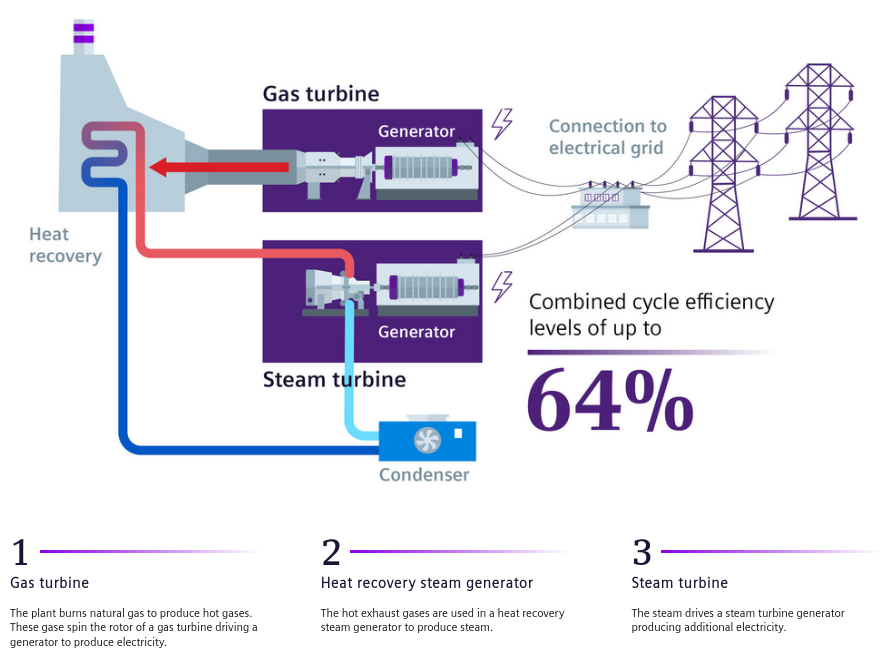

How do The Gas Turbines Work?

1. Compression: Air enters a multi-stage compressor (axial/centrifugal), where rotating and stationary blades progressively reduce flow area, increasing pressure and temperature.

2. Combustion: Fuel is injected into this dense, high-pressure air and actively ignited (initially). The resulting self-sustaining reaction generates intensely hot gases (>1,500°C), causing rapid expansion. Continuous fuel injection and flame stabilization maintain the self-sustaining reaction.

3. Expansion (Energy Transfer): These intensely hot gases rapidly expand through stator vanes/nozzles, accelerating to very high velocity and impacting the turbine blades, and transferring the kinetic energy. The spinning turbine rotor drives the compressor and electric generator.

The turbine blades connect to both the compressor and generator in a single-shaft design, or they may drive each component separately in a two-shaft design.

4. Exhaust: The residual hot exhaust gases exit the turbine at ~550°C.

While simple-cycle plants release exhaust heat directly into the atmosphere, wasting valuable thermal energy at ~550°C, combined-cycle power plants (CCPP) capture this resource using a Heat Recovery Steam Generator (HRSG). Here, exhaust gases transfer their residual heat to water, converting it into high-pressure steam that drives a secondary steam turbine operating on a closed-loop Rankine cycle. This fuel-free process generates additional electricity, cooling exhaust to ~120°C while boosting net plant efficiency beyond 60% (peaking around 64%).

In a CCPP, a single-shaft configuration means that the gas turbine and the steam turbine are connected to and drive a single generator on the same shaft. In contrast, a multi-shaft configuration uses separate generators for the gas turbine and the steam turbine. Single-shaft configurations have a smaller footprint due to fewer mechanical components, and may be more cost-effective, while offering greater overall efficiency compared to multi-shaft designs.

The thermal energy from these exhaust gases, emitted at temperatures ranging from 120°C to 140°C, can be further utilised to improve overall efficiency.

Combined Heat and Power Plants

Combined Heat and Power (CHP) plants, also known as co-generation plants, optimize overall energy efficiency by capturing the thermal energy from exhaust gases emitted at temperatures between 120°C and 140°C. Through the use of heat exchangers, this residual thermal energy is extracted and effectively utilized for district heating systems or various industrial process applications, especially vital in cold-climate regions. This dual-purpose approach enhances the overall sustainability and efficiency of the energy production process.

Modern gas plants offer a crucial strategic advantage as a lower-carbon bridge and a reliable backup for renewable energy. Their core strength lies in dispatchability and flexibility, to provide on-demand power and rapidly ramp production up or down to balance grid fluctuations caused by variable wind and solar output. Efficient technologies used in CCGT and CHP generate significantly more energy (Electricity and thermal) per unit of fuel and CO2 emissions compared to legacy coal or oil plants. Reliability is assured through mature, proven technology, ensuring predictable output. Geographic flexibility allows for relatively quick construction near demand centres, pipelines, or LNG facilities. Furthermore, gas plants provide essential grid stability services, including inherent rotational inertia (though less than traditional steam plants), voltage support, frequency response, and critical black-start capability to restore power after outages.

Environmental Considerations & Alternative Fuels:

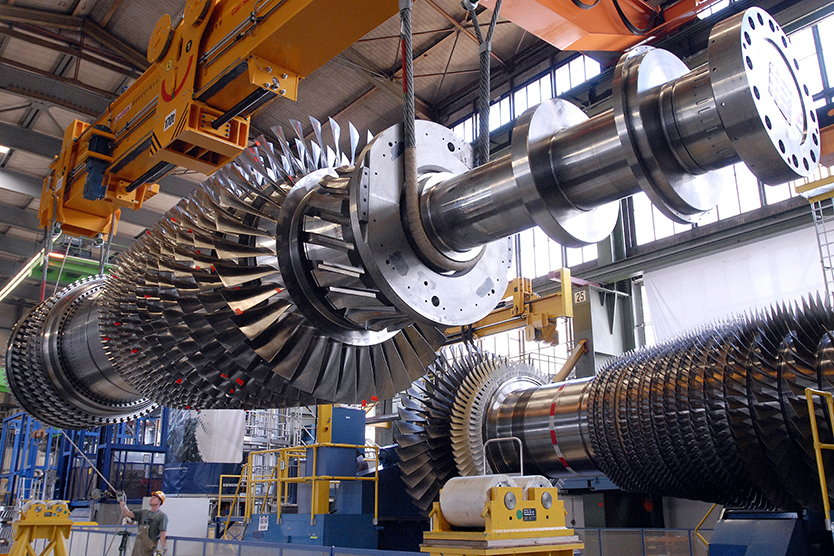

Natural gas remains the primary fuel for gas power plants due to its high heating value, clean combustion characteristics and established infrastructure. Let us compare the emissions from coal power plants, gas power plants using natural gas/methane, and alternative fuels such as bio-gas, ammonia, hydrogen and hydrogen blends.

- The Coal: Coal is primarily composed of carbon and contains variable amounts of hydrogen, sulfur, oxygen, and nitrogen, with varying percentages depending on the type of coal. Most of the energy from coal comes from the carbon content, and is the primary source of its CO₂ emissions. Furthermore, the inherent sulfur and nitrogen release SO₂ and NOx during combustion. Finally, its solid state often leads to incomplete combustion, resulting in the release of particulate matter and carbon monoxide. The power plants that rely on coal combustion are thus the most polluting.

- Methane/Natural Gas: Methane, chemically known as CH₄, is a vital component of natural gas. Natural gas also contains other family members of the methane, namely alkanes CₙH₂ₙ₊₂ (methane, ethane, propane and butane). The primary component of natural gas is methane (exceeding 80%), with the remainder comprising other alkane hydrocarbons and trace levels of gases such as N₂ and CO₂. Natural gas and methane, having a lower energy-to-carbon ratio, coupled with their complete combustion, result in lower CO₂, zero SO₂ emissions, and no particulate matter. NOx emissions are drastically reduced, yet still present (highly dependent on the combustion technology used).

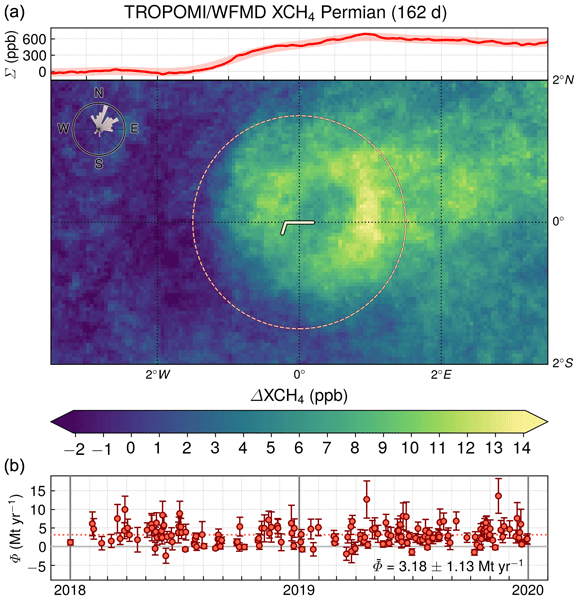

While natural gas burns cleaner than coal, methane leakage across the supply chain undermines its climate advantage. Methane is a potent greenhouse gas, with over 80 times the global warming potential of carbon dioxide over 20 years. A small leak can have a significant impact on the environment. Despite decades of refining extraction and transport technology, the risk of accidental venting and leaks remains a persistent and critical environmental challenge. The climate benefit of natural gas over coal is contingent upon maintaining a low methane leakage rate across the entire supply chain. Studies indicate that the breakeven point, where the comparative climate advantage is lost, occurs when total methane leakage exceeds approximately 2.5 - 3.0% of gas production. While industry-reported averages often suggest leakage rates below this threshold, empirical data from satellite and aerial surveys frequently reveal regional leakage rates that surpass this critical breakeven point due to widespread super-emitting sites. This gap highlights the crucial need for robust monitoring and repair programs. Using infrared cameras and satellite technology to repair methane leaks promptly is essential to ensure natural gas acts as a bridge fuel and does not accelerate climate change.

- Bio-gas/Bio-Methane: A superior alternative is bio-methane, a renewable gas derived from the anaerobic digestion of agricultural, food and other organic waste. This process actively prevents methane from being released into the atmosphere during natural decomposition. By purifying this captured bio-gas to pipeline quality, we create a drop-in fuel that not only generates dispatchable electricity but also closes the carbon loop, turning a vital environmental liability into a clean energy asset and achieving substantial greenhouse gas savings. However, the viability of this green alternative is entirely dependent on two foundational pillars: waste segregation at the source and the strategic deployment of advanced anaerobic digestion facilities.

- Hydrogen blends and Hydrogen: While hydrogen is considered a cornerstone of a carbonized energy future, its integration into gas turbines comes with significant engineering and environmental complexities that must be addressed.

- First, its use involves a non-trivial efficiency penalty. Hydrogen's lower energy density by volume and different combustion properties require modifications to fuel systems reduce turbine efficiency. However, this is widely considered an acceptable trade-off for the potential of carbon-free dispatchable power.

- The second, and more critical, issue is the source of the hydrogen itself. The popular colour-coded taxonomy is crucial here:

- Grey Hydrogen: The dominant form today, produced via steam methane reforming (SMR) of natural gas without carbon capture, results in significant CO₂ emissions.

- Blue Hydrogen: This is grey hydrogen coupled with carbon capture and storage (CCS). While touted as a low-carbon solution, its climate benefit is contingent on capturing a very high percentage (>90%) of emissions. (not always achieved)

- Green Hydrogen: Produced via electrolysis using renewable electricity, this is the only truly carbon-neutral pathway at the point of production and is essential for realizing hydrogen's full climate potential.

- Finally, the claim that hydrogen "burns cleanly" requires vital nuance. While it produces zero CO₂ emissions during combustion, burning it in air (which is 78% nitrogen) presents a major challenge: thermal NOx formation. The extremely high flame temperatures of hydrogen cause atmospheric nitrogen and oxygen to dissociate and recombine into nitrogen oxides (NOx), a primary contributor to smog and acid rain (Zeldovich mechanism). To overcome this, advanced and expensive combustion systems and selective catalytic reduction (SCR) technology are used to mitigate emissions, ensuring that a shift to hydrogen does not simply trade one pollutant for another.

- Ammonia (NH₃): Offers a practical pathway to decarbonize gas power, leveraging its existing global infrastructure as a hydrogen carrier and industrial chemical. However, its toxicity and corrosive nature require stringent safety measures. Blending it with hydrogen improves combustion stability and enables finer control over the process. A key advantage is the ability to utilize a portion of the ammonia fuel for Selective Catalytic Reduction (SCR), drastically cutting NOx emissions from over 700 ppm to below 10 ppm. While promising, this approach mandates complex and expensive retrofits of existing plants to precisely manage combustion dynamics and handle the new fuel safely, representing a significant investment hurdle.

| Technology | CO₂ (grams/kilowatt-hour) | NOx (grams/kilowatt-hour) | SO₂ (grams/kilowatt-hour) | PM (grams/kilowatt-hour) | Other |

|---|---|---|---|---|---|

| Coal Power Plant | 820–1100 | 0.3–1.5 | 0.13–1.6 | 0.01–0.2 | Hg, CH₄ |

| Natural Gas CCGT | 370–490 | 0.05–0.1 (EU) / 0.08–0.1 (US) | Negligible | Negligible | – |

| Gas CHP | 310–490 | 0.05–0.1 | Negligible | Negligible | – |

| Hydrogen Blend (20%) | ~300–370 | ~0.06–0.12 | Zero | Negligible | – |

| Hydrogen (100%) | 0 | ~0.1–0.2 | Zero | Negligible | – |

| Ammonia | 0 | 0.8–1.0 | Zero | Negligible | NH₃ slip |

| Biogas/Biomethane | ~150–400 (avoided emissions included) | ~0.05–0.1 | Negligible | Negligible | NH₃, CH₄ slip |

Fuel slip refers to unburnt fuel that escapes into the atmosphere during the combustion process. The slip of unburnt methane (CH₄) or ammonia (NH₃) noted in the table represents an emissions challenge that must be technically managed to realize the full climate and air quality benefits of these alternative fuels.

While natural gas offers a clear emissions advantage over coal, its role as a transitional fuel is contingent on aggressively addressing methane leakage across the supply chain. The pathway to a decarbonized grid lies in the strategic integration of alternative fuels. Bio-methane presents a ready, circular solution by converting waste into clean energy, though it depends on robust waste management systems. Hydrogen and ammonia hold promise as zero-carbon fuels but face significant hurdles: hydrogen requires a shift to green production and advanced NOx mitigation, while ammonia demands complex plant retrofits and careful emissions management. No single alternative is a perfect drop-in solution; each requires substantial investment, infrastructure adaptation, and ongoing innovation to balance environmental benefits with technical and economic feasibility, ultimately shaping gas power plants' role in a secure, low-carbon energy future.

The Bridge to Renewables: Phasing Down as We Scale Up

The strategic value of gas power is not in its permanence, but in its ability to seamlessly phase out as cleaner technologies scale up. This requires a disciplined, forward-looking transition strategy with a clear end goal.

The Clear End Goal: A Diversified, Resilient Grid

The destination is a 100% clean grid, but this must also mean reliable and resilient. This system will be built on a foundation of:

- Deploying significantly more wind and solar capacity than peak demand to ensure ample generation even during sub-optimal weather.

- A diverse portfolio of both short-duration and long-duration storage to shift energy across days and weeks.

- High-Voltage Direct Current (HVDC) interconnections to move power efficiently across vast regions, balancing renewable surpluses and deficits, complemented by smart grids for optimal distribution.

- Leveraging technology to allow consumers to interact with the grid, temporarily reducing demand during periods of constraint instead of firing up a peak plant.

- A minority share of always-available, non-weather-dependent sources like geothermal, next-generation nuclear, or sustainably sourced hydrogen/bio-methane turbines to ensure stability during prolonged calm or dark periods.

The Phase-Down Strategy: From Workhorse to Safety Net

Gas plants must not operate as they do today. Their role must evolve with the deployment of the above solutions:

- As storage capacity and grid interconnections grow, the annual running hours of gas plants should sharply decrease. They must transition from providing base-load and load-following power to a purely peaking and reliability reserve role, operating only during extreme demand peaks or emergency shortages.

- Any new gas plant receiving approval must be certified to operate on alternative fuels (with the least emissions available in the region) from day one. This ensures it can transition to cleaner fuels and avoids becoming a stranded asset.

The Policy & Transition Framework: Building the Bridge, Not the Destination

Market forces alone will not orchestrate this decline. Proactive policy is essential to manage the transition and protect consumers and investors:

- Legislating steadily declining limits on grams of CO₂ per kWh forces the phase-out of unabated gas combustion. An EPS that drops to near zero (EU Net-zero 2050 goal) makes the continued operation of pure natural gas plants impossible.

- Putting a direct cost on carbon emissions makes renewable energy and storage increasingly cost-competitive, naturally accelerating the retirement of fossil assets.

- Regulators and investors must model scenarios where gas plants retire well before their economic lifespan ends. This risk must be priced into every new investment decision.

- Public funding should shift from supporting fossil infrastructure to aggressively deploying storage, modernizing the grid, and supporting R&D for long-duration storage and advanced geothermal.

Avoiding the Lock-In Trap

The greatest risk is overbuilding gas capacity today under the guise of it being a "bridge." A bridge that is too long or too permanent becomes a barrier.

- A gas plant built today has a 30-year technical lifespan. If a nation’s net-zero target is 2050, that plant must be phased out by 2045 at the latest. Building it in 2025 only gives it 20 years of operation, a crucial financial consideration.

- Investing billions in a new gas plant that may be forced to close in 15 years due to climate policy creates a massive financial risk for utilities and ratepayers who would be on the hook for the unpaid debt.

- An over-reliance on gas can create political and economic inertia, disincentivizing the rapid build-out of the renewable and storage assets that constitute the true end goal.

Gas power's role is to act as a dynamic stabilizer, its output inversely correlated to the success of our renewable build-out. Our policies must be designed not to extend their life, but to ensure their graceful and predictable exit from the energy stage.

Enabling the Future, Responsibly

Gas plants can only ever be a bridge, a short-term reliability backstop while we scale true decarbonization. Continued gas use must be tightly conditional with rapid, verifiable methane mitigation and monitoring; new plants built fuel-flexible and certified for low-carbon fuels; firm operating-hour limits and retirement dates to avoid lock-in; and fiscal/regulatory safeguards against stranded assets. At the same time, policymakers should accelerate unabated coal retirements and invest in alternatives: stronger grid interconnection, long-duration options (including flow batteries that are nearing commercial demonstration), expanded transmission, and distributed renewables. This mix of solutions working in tandem is what will deliver a reliable 100% renewable future.

For feedback or to report inaccuracies, kindly drop a mail at feedback@ecoethos.co

References

https://www.lazard.com/media/xemfey0k/lazards-lcoeplus-june-2024-_vf.pdf

https://www.iea.org/reports/global-methane-tracker-2024

https://www.sciencedirect.com/science/article/pii/S0360544224010193

https://ejournals.lib.hkbu.edu.hk/index.php/jaes/article/view/2796/2344

https://www.andovertechnology.com/wp-content/uploads/2023/09/CO2-and-NOx-from-NG-plants.pdf

https://www.europeanbiogas.eu/wp-content/uploads/2020/04/20200419-Background-paper_final.pdf

https://www3.epa.gov/ttnchie1/conference/ei20/session5/mmittal.pdf

https://www.andovertechnology.com/wp-content/uploads/2023/09/CO2-and-NOx-from-NG-plants.pdf